Many innovative batteries are becoming available to people today as the popularity of electric vehicles increases. Yet people lack basic knowledge about batteries: how they are damaged too quickly, how to repair damaged batteries, how to maintain them, etc. We will discuss these issues for your reference. Lead-acid batteries are usually used in electric vehicles and the electrolyte is colloidal, divided into four voltages: 24V, 36V, 48V, and 60V.

Batteries can be damaged for several reasons, which can roughly be broken down into the following five categories:

1. Overcharge

Overcharging a battery can damage it chemically and physically, causing damage to the battery.

Chargers are most likely to malfunction if they are overcharged. Currently, the charging voltage settings for electric vehicles are generally safe. In general, the charging voltage is 1.2 times the voltage of the battery. As an example, to charge a 48V battery, the charging voltage must be set between 57.4 and 57.2 volts. A battery’s voltage gradually drops as it is discharged. Charger voltage component failure will cause the battery charging to fail. The battery charger current will continuously input charging current to the battery, causing the voltage to rise, increasing the temperature of the electrolyte, which will result in the expansion of the battery shell.

Additionally, the “overcharge” is caused by an imbalance in battery voltages. When charging an electric vehicle, several battery packs are charged simultaneously. Because the battery charger charges batteries based on their overall voltage, the battery with the highest voltage will be fully charged first, and the battery with the lowest voltage will be fully charged later or continuously, so the battery that is fully charged first will have been overcharged. Batteries will be relatively unaffected if the pressure difference is very small. “Overcharging” can also lead to more intense thermal reactions until the battery is fully charged. This is the result of a large “pressure difference.”

2. Loss of Water

Battery capacity decreases primarily due to “water loss.” Lead-acid batteries are the most common battery type in electric vehicles. These types of batteries are commonly referred to as sealed and maintenance-free. Is there a reason for this phenomenon? There is a very simple reason. The electrolysis reaction of the battery involves water as an essential component. It is easy for batteries to generate heat and water vapor if they are overcharged, discharged with high current, have an internal resistance that is increased, or shorted out. The seals of sealed batteries trap the water vapor.

The density difference in the battery shell material will cause a very small percentage of them to be lost. Water will accumulate and cause the battery to deteriorate. After using an electric vehicle for more than six months, a battery tends to lose its ability to hold water. Overheating due to water loss is more severe when the motor power is high.

3. Loss of electricity

The term “power deficit” refers to a phenomenon when the battery power is insufficient and the voltage is low, which leads to the battery plate coating being damaged. Any appliance outside of standard range risks short-circuiting or even being burned. When electrical appliances fall within this range, they cannot start or function normally, and even reduce their lifespan.

The average user recharges their electric vehicles every few days, and some of them travel more than 60% of the new battery’s nominal range every day. Having insufficient battery voltage leads to ineffective battery performance. Therefore, a decrease in battery capacity is important to consider. Due to these factors, the onboard electrical appliances will result in a low battery voltage. As the battery plate begins to breakdown, a layer of lead will gradually peel off.

4. Vulcanization of the Electrode Plate

On the plate, hard white crystals of lead sulfate form, which are very hard to convert into active lead sulfate during charging. This refers to sulfurization or sulfation. When lead sulfate particles are left in the electrolyte after an over discharge or discharge for a very long time, they dissolve in the electrolyte and become saturated. Lead sulfate will reconstitute at low temperatures, but will precipitate as crystals at higher temperatures.

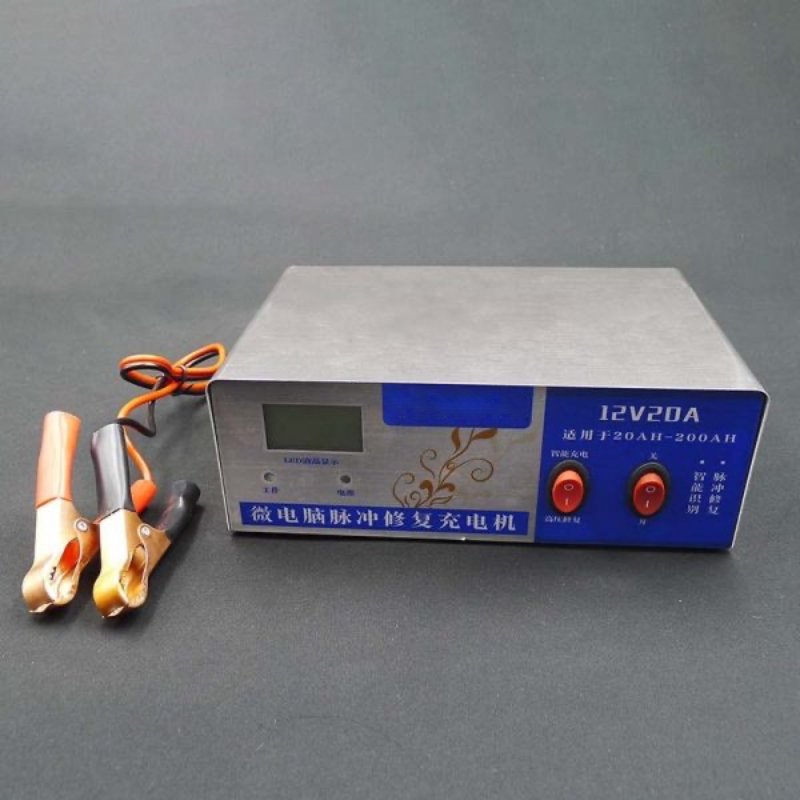

Also Read: Solve Battery Problems with a Car Battery Charger

Through this process, previously precipitated particles continue to develop and grow due to temperature fluctuations, resulting in enlarged crystal grains. When charged, this kind of lead sulfate has poor conductivity, a small dissolution rate, a low solubility, and a low solubility. These characteristics lead to reduced capacity and short lifespan. Battery capacity is reduced by sulfurization, but more importantly, high current damages the battery plates, which is the main factor causing reduced battery capacity in electric vehicles.

5. Starting, Accelerating, and Overloading with High Current Discharge

It is common for electric vehicles to generate up to 20A to 50A of current when they are started or accelerated. In general, the normal discharge current is controlled within 10A according to the motor power of the electric vehicle. When the instantaneous current is too large, the electrolysis reaction will be greatly accelerated, and this will obviously affect the electrode plate coating. Due to the instantaneous high current pulling, the lead layer powder on the electrode plate will gradually fall off, resulting in the electrolyte turning black, and the battery will have to be scrapped.

The excess weight increases the charging load on the battery. When the whole plate is exposed to high voltage for a long time, the coating becomes damaged and the plate starts to soften. In addition, electric vehicles will also be more likely to brake if road conditions are bad. For example, traffic snarls, potholes, and red lights. All of these can lead to high current discharges. Motor power determines the discharge current and the likelihood of battery damage, so the higher the motor power, the higher the discharge current. In this way, it can lead to shorter service life of the battery.